Struggling with fiber core manufacturing1 complexity? Poor quality control leads to signal loss and production failures.

Fiber core manufacturing involves preform creation using chemical vapor deposition, followed by precision drawing at 2000°C temperatures with real-time diameter control and protective coating application.

Getting into fiber core manufacturing1 feels overwhelming at first. The technology is complex, and the investment is significant. I remember when I first started working with optical fiber production lines at HONGKAI. The precision required seemed impossible to achieve. Every step in the process demands exact control, from the initial glass preparation to the final coating application. Making mistakes at any stage can result in unusable fiber that fails to meet performance standards. Understanding each phase of the manufacturing process is essential for success. Let me walk you through the complete process, step by step, so you can build a reliable production line that consistently produces high-quality fiber cores.

What Materials Do You Need for Fiber Core Production?

Raw material quality determines final fiber performance. Using impure chemicals leads to signal attenuation and fiber breaks during production.

Ultra-pure silicon tetrachloride and germanium tetrachloride are converted to glass through controlled chemical reactions at temperatures exceeding 1500°C in specialized furnaces.

The foundation of any high-quality fiber core starts with the right materials. I learned this lesson hard during my early days in the industry. We had a batch of fiber that consistently failed quality tests, and it took weeks to trace the problem back to contaminated raw materials. The purity requirements2 for optical fiber manufacturing are extreme, far beyond what most other industries require.

Primary Chemical Components

The core materials for optical fiber production are surprisingly simple in concept but incredibly demanding in execution. Silicon tetrachloride (SiCl4) is the primary source of silica glass, forming the backbone of the fiber structure. This chemical must achieve purity levels of 99.999% or higher. Even trace amounts of impurities can cause significant optical losses or create weak points, leading to fiber breaks during the drawing process.

Germanium tetrachloride (GeCl4) acts as the dopant material that increases the refractive index of the core relative to the cladding. The precise concentration of germanium determines the finished fiber’s numerical aperture and light-gathering capability. We typically use tiny amounts of germanium for single-mode fibers, usually less than 3% by weight. Multimode fibers require higher concentrations, sometimes reaching 8-12% in the core region.

Chemical Reaction Process

The transformation from liquid chemicals to solid glass occurs through a carefully controlled oxidation process. The basic reaction for silica formation follows this equation: SiCl4 + O2 → SiO2 + 2Cl2. This reaction requires temperatures between 1500°C and 1800°C to proceed efficiently. The germanium reaction follows a similar pattern: GeCl4 + O2 → GeO2 + 2Cl2.

What makes this process challenging is maintaining consistent reaction conditions throughout the entire deposition cycle. Temperature variations of even 10°C can cause composition changes that affect the final fiber’s optical properties. The oxygen flow rate must remain stable within 1% to ensure complete oxidation of the chloride compounds. Any unreacted chlorides can create absorption centers that increase optical loss.

Purity Requirements and Testing

The purity standards for fiber optic materials exceed those of most semiconductor applications. Water content must stay below 1 part per million, as hydroxyl groups create firm absorption peaks at 1380 nm wavelength. Metal impurities like iron, copper, and chromium must remain below 10 parts per billion each since these elements cause additional absorption and scattering losses.

We test every batch of incoming chemicals using inductively coupled plasma mass spectrometry (ICP-MS) to verify purity levels. Gas chromatography helps identify organic contaminants that could affect the glass formation process. These tests add cost and time to the production schedule but prevent much more expensive problems later in the manufacturing process.

| Material | Purity Requirement | Key Contaminants | Testing Method |

|---|---|---|---|

| SiCl4 | >99.999% | H2O, Fe, Cu, Cr | ICP-MS, GC |

| GeCl4 | >99.99% | H2O, Metal ions | ICP-MS, Karl Fischer |

| O2 | >99.95% | H2O, Hydrocarbons | GC, Moisture analyzer |

| Carrier gases | >99.999% | H2O, O2, Hydrocarbons | GC, Trace oxygen analyzer |

Storage and Handling Considerations

Proper storage of these chemicals requires specialized facilities. Silicon and germanium tetrachlorides are highly reactive with moisture, forming hydrochloric acid that corrodes equipment and creates safety hazards. We store these materials in sealed stainless steel containers under a dry nitrogen atmosphere. The storage area maintains temperature control within ±2°C and relative humidity below 5%.

Handling procedures follow strict protocols to prevent contamination. All transfer lines use electropolished stainless steel tubing with VCR fittings to minimize particle generation. We purge all lines with ultra-high purity nitrogen before introducing process chemicals. Personnel wear cleanroom suits and follow decontamination procedures when entering the chemical storage areas.

The investment in proper material handling pays dividends in consistent fiber quality. I have seen production lines shut down for days because of contaminated chemicals that could have been prevented with better storage practices. The cost of maintaining ultra-clean conditions is minimal compared to the expense of producing defective fiber.

How Do You Create the Glass Preform?

Perform quality directly impacts fiber characteristics. Inconsistent deposition leads to diameter variations and optical losses throughout the fiber length.

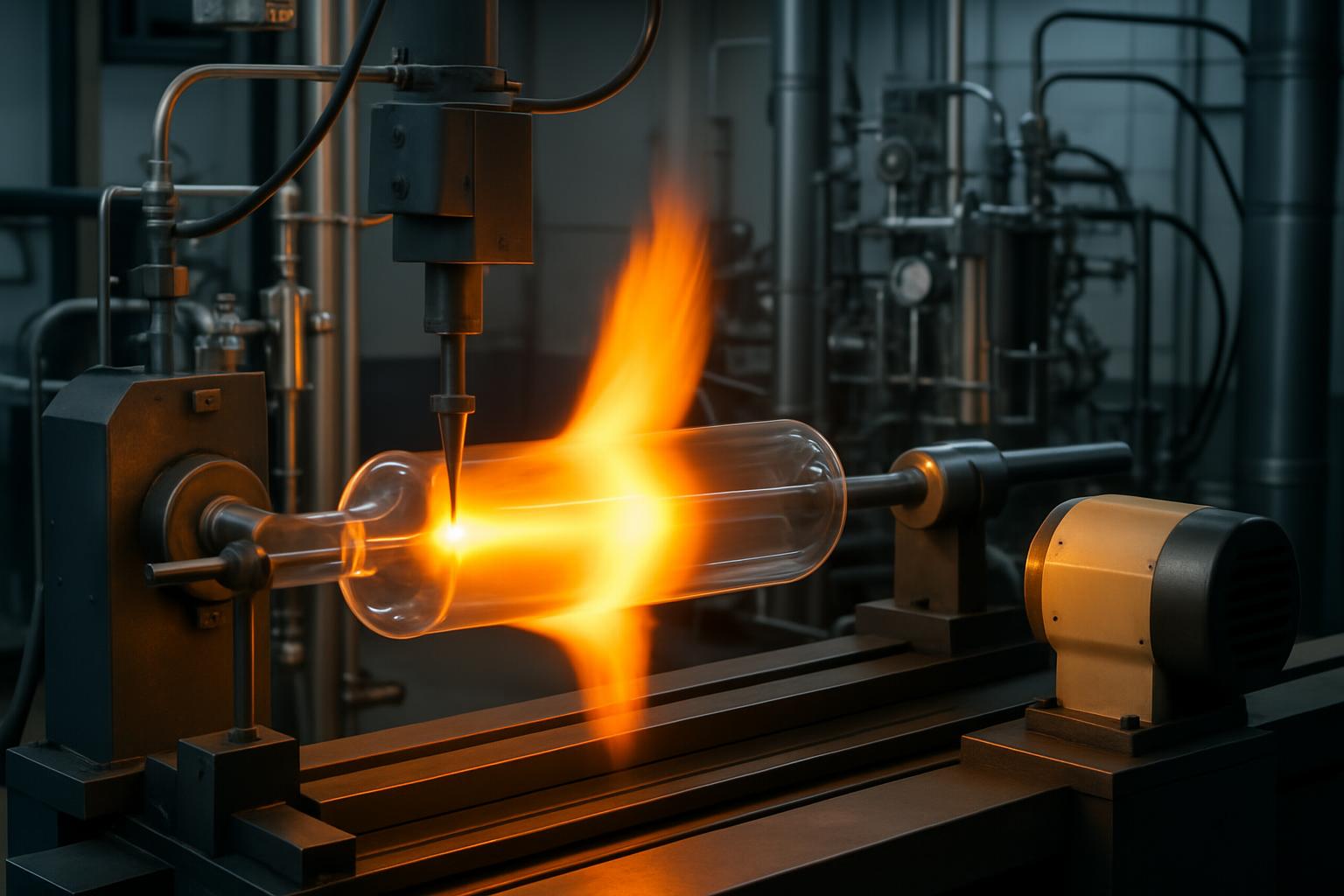

MCVD and OVD processes deposit glass layers inside rotating tubes using precise temperature and chemical flow control, creating performs up to 1 meter long

Creating the glass preform represents the most critical phase of fiber core manufacturing1. This process determines the fundamental optical and mechanical properties of the finished fiber. I have spent countless hours optimizing preform fabrication parameters, and I can tell you that small changes in this stage dramatically affect the final product quality.

Modified Chemical Vapor Deposition (MCVD) Process

The MCVD process3 remains the most widely used method for creating high-quality preforms. The process begins with a pure silica substrate tube, typically 15-25 mm in outer diameter and 800-1200 mm in length. This tube must meet stringent specifications for roundness, concentricity, and surface finish. Any defects in the substrate tube will propagate through the entire manufacturing process.

The substrate tube mounts horizontally on a precision lathe capable of maintaining rotational speeds between 10-100 RPM with minimal vibration. A traversing burner system moves along the length of the tube, providing the heat necessary for the chemical reactions. The burner typically uses a hydrogen-oxygen flame that reaches temperatures of 1900-2000°C at the tube surface.

Chemical vapors flow through the inside of the rotating tube in a carefully controlled sequence. The flow rates must remain stable within 0.5% to ensure uniform deposition. Mass flow controllers regulate each chemical stream independently, allowing precise control of the glass composition. A typical deposition cycle might involve 50-200 individual passes, each adding only a few micrometers thick layer.

The deposition process creates what we call "soot" – submicron glass particles that form in the hot zone and deposit on the inner wall of the tube. The high temperature consolidates these particles into dense, transparent glass as the burner passes over the deposited soot. The consolidation temperature must be carefully controlled to prevent bubble formation while ensuring complete densification.

Outside Vapor Deposition (OVD) Process

The OVD process4 offers advantages for producing large preforms with complex refractive index profiles. Instead of depositing inside a tube, OVD builds up glass layers outside a rotating mandrel or "bait rod." This approach allows better control of the core-to-cladding ratio and enables the production of preforms with larger core diameters.

The OVD process4 begins with a pure silica or alumina bait rod mounted vertically in a deposition chamber. Multiple burners traverse the length of the rod, each capable of depositing different glass compositions. The core layers deposit first, followed by successive cladding layers. This outside-in approach provides excellent control over the refractive index profile.

One significant advantage of OVD is the ability to produce very large preforms. While the size of available substrate tubes typically limits MCVD, OVD can create preforms over 150 mm in diameter and 1.5 meters in length. These large forms enable longer fiber draws and better production economics.

The consolidation step in OVD requires special attention. After completing the deposition, the porous preform goes into a consolidation furnace where it is heated to 1500-1600°C in a controlled atmosphere. The bait rod is removed either before or after consolidation, depending on the specific process variant. The resulting preform must be perfectly round and free from internal stress that could cause problems during fiber drawing.

Quality Control During Preform Fabrication

Quality control during preform fabrication involves continuous monitoring of multiple parameters. Temperature measurement uses optical pyrometers that can accurately measure flame temperature without contact. These measurements help maintain consistent deposition conditions throughout the process.

Refractive index profiling provides the most critical quality assessment for preforms. We use a preform analyzer that measures the index profile across the preform diameter using interferometric techniques. This measurement reveals the core diameter, numerical aperture, and index profile shape. Any deviations from specifications require process adjustments before continuing production.

Geometric measurements ensure the preform meets dimensional requirements. We measure outer diameter, concentricity, and straightness using precision measurement systems. The preform must maintain roundness within 0.1% and concentricity within 0.5% to produce acceptable fiber.

| Parameter | MCVD Specification | OVD Specification | Measurement Method |

|---|---|---|---|

| Core diameter | 8-12 μm | 8-15 μm | Refractive index profiler |

| Numerical aperture | 0.12-0.22 | 0.12-0.25 | Refractive index profiler |

| Concentricity | <0.5% | <0.3% | Geometric measurement |

| Roundness | <0.1% | <0.1% | Geometric measurement |

| Attenuation | <0.5 dB/km | <0.3 dB/km | Cutback measurement |

Process Optimization and Troubleshooting

Optimizing preform fabrication requires understanding the complex interactions between temperature, flow rates, and deposition chemistry. The systematic design of experiments works better than trial-and-error approaches. We typically vary one parameter at a time while holding others constant, then analyze the results using statistical methods.

Common problems include core-cladding interface defects, refractive index variations, and geometric irregularities. Interface defects often result from contamination or temperature fluctuations during the transition between core and cladding deposition. Index variations can stem from flow rate instabilities or burner temperature changes. Geometric problems usually trace back to substrate tube quality or lathe vibration issues.

Preventive maintenance plays a crucial role in consistent preform quality. We replace burner components on a scheduled basis to prevent performance degradation. Flow controllers require regular calibration to maintain accuracy. The lathe system needs periodic alignment checks to ensure proper tube rotation and burner positioning.

The time investment in perfecting preform fabrication pays enormous dividends in downstream processing. A high-quality preform draws easily into fiber with consistent properties, while a poor preform causes breaks, diameter variations, and optical losses that can make the entire production run unusable.

What Equipment Is Essential for Fiber Drawing?

Wrong equipment choices lead to production failures. Inadequate drawing systems cause fiber breaks, diameter variations, and coating defects that render the product unusable.

Drawing towers with graphite furnaces, diameter gauges, coating applicators, and tension control systems ensure consistent fiber quality at drawing speeds up to 25 meters per second.

The fiber drawing process transforms the solid glass preform into hair-thin optical fiber through a carefully orchestrated sequence of heating, pulling, and coating operations. After years of working with different drawing systems, the quality of the equipment directly determines your production success. Every component must work in perfect harmony to achieve the precision required for optical fiber manufacturing.

Drawing Tower Structure and Design

A modern fiber drawing tower5 stands 10-15 meters tall, providing the vertical space needed for proper fiber formation and cooling. The tower structure must be extremely rigid to prevent vibrations that could cause diameter variations. We typically use heavy steel construction with vibration isolation systems to minimize external disturbances.

The tower houses multiple zones, each serving a specific function in the drawing process. The top section contains the preform feed mechanism and furnace. The middle section provides space for fiber cooling and diameter measurement. The bottom section houses the coating application system, curing ovens, and take-up equipment.

Environmental control within the tower is critical for consistent results. We maintain positive air pressure using filtered air to prevent contamination. Temperature control keeps the ambient conditions stable within ±2°C. Humidity control prevents moisture from affecting the coating process. These environmental systems operate continuously, even during production shutdowns.

High-Temperature Furnace Systems

The furnace represents the heart of the drawing operation. Most modern systems use graphite-resistant heating elements that can reach temperatures up to 2200°C. The furnace chamber typically measures 100-150 mm in diameter and 200-300 mm in height, providing uniform heating across the preform tip.

Temperature control accuracy is paramount for consistent fiber diameter. We use multiple thermocouples and optical pyrometers to monitor furnace temperature with ±1°C precision. The control system responds to temperature variations within seconds to maintain stable drawing conditions.

Furnace atmosphere control prevents oxidation of the graphite heating elements and ensures clean fiber formation. We typically use argon or nitrogen atmosphere with oxygen levels below 10 ppm. Gas flow rates are carefully controlled to provide adequate purging without creating turbulence that could affect fiber formation.

The preform feed mechanism must position the preform precisely in the furnace hot zone. Servo-controlled feed systems can maintain position accuracy within ±0.1 mm while compensating for preform consumption during drawing. Feed rate control allows adjustment of the drawing tension and fiber diameter.

Diameter Measurement and Control

Real-time diameter measurement is essential for producing fiber within specification. Laser-based measurement systems can detect diameter changes as small as 0.1 μm with response times under 1 millisecond. These systems typically use laser diffraction or shadow techniques to measure the fiber diameter just below the furnace.

The diameter control system uses feedback loops to maintain the target diameter by adjusting the drawing speed. When the diameter increases above the target, the system increases the capstan speed to stretch the fiber thinner. When the diameter decreases, the system reduces the speed to allow the fiber to thicken. This control loop operates continuously during drawing.

Advanced control algorithms can predict diameter changes based on preform geometry and drawing conditions. These predictive systems help maintain tighter diameter tolerances by making adjustments before significant variations occur. Machine learning techniques are increasingly used to optimize control parameters based on historical production data.

| Component | Specification | Tolerance | Control Method |

|---|---|---|---|

| Furnace temperature | 1900-2100°C | ±1°C | PID control with optical feedback |

| Fiber diameter | 125 μm | ±1 μm | Laser measurement with speed feedback |

| Drawing speed | 10-25 m/s | ±0.1% | Servo-controlled capstan |

| Coating thickness | 62.5 μm | ±2.5 μm | Pressure and flow control |

Coating Application Systems

The coating system applies protective polymer layers to the bare glass fiber immediately after formation. The coating must be applied concentrically and uniformly to prevent micro-bending losses and provide mechanical protection. Most systems use pressure die applicators that force liquid coating material around the fiber.

Primary coating application occurs first, typically using a soft, low-modulus acrylate polymer. This coating cushions the fiber against micro bending and provides the first level of protection. The coating thickness is usually 32.5 μm, bringing the total diameter to 190 μm.

A secondary coating application follows, using a more rigid polymer that provides mechanical protection and handling strength. This coating adds another 32.5 μm thickness, resulting in a final coated diameter of 250 μm. The secondary coating must bond well to the primary coating while maintaining flexibility.

Coating concentricity is critical for fiber performance. Eccentric coatings can cause differential stress that leads to polarization mode dispersion in single-mode fibers. We monitor coating concentricity using optical measurement systems and adjust die alignment as needed to maintain specifications.

UV Curing Systems

Ultraviolet curing systems polymerize the liquid acrylate coatings into solid protective layers. The curing process must be complete and uniform to ensure proper coating properties. Incomplete curing can lead to tacky surfaces and poor mechanical properties.

UV lamp systems typically use medium-pressure mercury lamps that emit broad-spectrum UV radiation. The lamps are arranged in arrays that surround the coated fiber, ensuring uniform exposure from all angles. Lamp intensity and exposure time are carefully controlled to achieve complete curing without overheating the fiber.

The nitrogen atmosphere in the curing ovens prevents oxygen inhibition of the polymerization reaction. Oxygen can interfere with free radical polymerization, leading to incomplete curing and poor coating properties. We maintain oxygen levels below 50 ppm in the curing chambers.

Tension Control and Take-Up Systems

Tension control throughout the drawing process is essential for consistent fiber properties. Excessive tension can cause fiber breaks or diameter variations, while insufficient tension can lead to loose winding and handling problems. We typically maintain drawing tensions between 50-150 grams.

The capstan system provides the primary pulling force for fiber drawing. Precision servo motors control the capstan speed with accuracy better than 0.01%. The capstan surface must be perfectly smooth to prevent fiber damage, and we use specialized coatings or materials to ensure gentle fiber handling.

Take-up systems wind the finished fiber onto spools for storage and shipping. The winding pattern must prevent fiber damage while allowing easy unwinding for subsequent processing. We use precision traverse mechanisms to create controlled winding patterns with appropriate tension distribution.

Dancer systems provide tension buffering between the capstan and the take-up reel. These mechanical systems use weighted arms or pneumatic cylinders to maintain constant tension despite variations in take-up speed or spool diameter changes. Proper dancer adjustment is critical for preventing fiber breaks and maintaining consistent winding tension.

How Do You Control Fiber Quality During Production?

Quality control prevents costly production defects. Without proper monitoring, entire production runs can fail specification requirements, resulting in significant material and time losses.

Real-time monitoring of diameter, coating thickness, and mechanical properties using laser gauges and automated feedback systems ensures consistent fiber quality throughout production.

Quality control in fiber core manufacturing requires a comprehensive approach that monitors every aspect of the production process. I have learned through experience that catching problems early saves enormous amounts of time and material. The key is implementing measurement systems that provide immediate feedback so operators can make corrections before defects propagate through the entire production run.

Real-Time Process Monitoring

Modern fiber drawing systems incorporate multiple real-time monitoring systems that track critical parameters continuously during production. Diameter measurement systems use laser diffraction techniques to monitor fiber diameter with sub-micron accuracy. These systems can detect diameter variations that occur over distances as short as a few centimeters, allowing immediate process adjustments.

Coating thickness monitoring uses optical techniques to measure both primary and secondary coating layers. Capacitive sensors can also detect coating thickness variations by measuring the dielectric properties of the coating materials. These measurements help ensure that the coating provides adequate protection while maintaining the target outer diameter.

Tension monitoring systems use load cells to measure the drawing force continuously. Sudden changes in tension can indicate problems with the preform, furnace conditions, or coating application. The monitoring system can trigger automatic adjustments or alert operators to potential issues before they cause fiber breaks.

Temperature monitoring extends beyond the furnace to include coating cure ovens and ambient conditions throughout the drawing tower. Thermal imaging systems can detect hot spots or temperature variations that might affect fiber quality. Environmental monitoring tracks humidity, air pressure, and contamination levels that could impact the production process.

Optical Property Testing

Optical testing during production focuses on the parameters that determine fiber performance in communication systems. Attenuation measurement uses the cutback method to determine optical loss at key wavelengths. For multimode fibers, we typically test at 850 nm and 1300 nm. Single-mode fibers require testing at 1310 nm and 1550 nm.

Bandwidth testing for multimode fibers uses either overfilled launch (OFL) or differential mode delay (DMD) techniques. OFL testing provides a simple measurement of the fiber’s information-carrying capacity, while DMD testing gives more detailed information about the refractive index profile quality. These tests help ensure that the fiber will meet system performance requirements.

Numerical aperture measurement verifies that the core-cladding index difference meets specifications. This parameter directly affects the light-gathering capability of multimode fibers and the cutoff wavelength of single-mode fibers. We use far-field scanning techniques to measure the numerical aperture with high accuracy.

Mode field diameter measurement for single-mode fibers uses near-field or far-field scanning techniques. This parameter affects splice loss and connector performance, making it critical for system compatibility. The measurement must be performed at the operating wavelength to ensure accuracy.

Mechanical Property Testing

Mechanical testing ensures that the fiber can withstand the stresses encountered during installation and operation. Proof testing applies a controlled tensile stress to every meter of fiber to screen out weak points that could cause failures in service. The proof test level is typically set at 100 psi (0.69 GPa) for standard telecommunications fiber.

Coating adhesion testing verifies that the polymer coatings bond properly to the glass surface and to each other. Poor adhesion can lead to coating delamination during handling or environmental exposure. We use strip force measurements to quantify the adhesion strength and ensure it meets specification requirements.

Bend testing evaluates the fiber’s resistance to macro-bending and micro-bending losses. Macrobending tests wrap the fiber around mandrels of various diameters to simulate installation conditions. Microbending tests apply controlled lateral pressure to mimic the effects of cable manufacturing and environmental stresses.

Environmental testing exposes fiber samples to temperature cycling, humidity exposure, and chemical environments that might be encountered in service. These tests help predict long-term reliability and identify potential failure modes before they occur in the field.

| Test Parameter | Standard | Frequency | Acceptance Criteria |

|---|---|---|---|

| Attenuation (1310 nm) | ITU-T G.652 | Every 2 km | <0.35 dB/km |

| Attenuation (1550 nm) | ITU-T G.652 | Every 2 km | <0.25 dB/km |

| Mode field diameter | ITU-T G.652 | Every 2 km | 9.2 ± 0.4 μm |

| Proof test | IEC 60793-1-30 | 100% | 100 kpsi survival |

| Coating diameter | IEC 60793-1-20 | Continuous | 245 ± 5 μm |

Statistical Process Control

Statistical process control6 (SPC) techniques help identify trends and variations in the manufacturing process before they result in out-of-specification products. Control charts track key parameters over time, showing both the average values and the variation around those averages. When measurements fall outside control limits, the system alerts operators to investigate potential causes.

Process capability studies quantify how well the manufacturing process can meet specification requirements. These studies calculate capability indices like Cp and Cpk that indicate whether the process variation is slight enough to produce an acceptable product consistently. Regular capability studies help identify opportunities for process improvement.

Design of experiments (DOE) techniques help optimize process parameters and understand the relationships between different variables. By systematically varying process conditions and measuring the results, we can identify the optimal operating points and understand which parameters have the most significant impact on product quality.

Correlation analysis helps identify relationships between different measurements that might not be obvious. For example, we might discover that coating thickness variations correlate with furnace temperature fluctuations, leading to improved process control strategies.

Automated Quality Systems7

Modern fiber production lines incorporate automated quality systems that can make real-time adjustments based on measurement feedback. These systems use advanced control algorithms to maintain product quality with minimal operator intervention. Machine learning techniques are increasingly used to predict quality issues before they occur.

Automated data collection systems record all process parameters and quality measurements in databases that can be analyzed for trends and patterns. This historical data helps identify the root causes of quality problems and supports continuous improvement efforts.

Automated rejection systems can remove out-of-specification fiber from the production stream without stopping the drawing process. These systems use pneumatic or mechanical devices to cut and remove defective sections while maintaining production continuity.

Integration with enterprise resource planning (ERP) systems allows quality data to be shared across the organization for production planning, customer reporting, and regulatory compliance. This integration helps ensure that quality information is available when and where it is needed for decision-making.

What Are Common Manufacturing Problems and Solutions?

Production issues can halt entire manufacturing lines. Unresolved problems lead to equipment damage, material waste, and missed delivery commitments that damage customer relationships.

Fiber breaks8, diameter variations, and coating defects require systematic troubleshooting and preventive maintenance protocols to maintain consistent production quality.

Manufacturing problems in fiber core production can be frustrating and expensive. I have encountered virtually every type of issue that can occur in this process, from simple operator errors to complex equipment failures. The key to successful troubleshooting is understanding the root causes and implementing systematic approaches to problem resolution.

Fiber Break Issues

Fiber breaks8 represent one of the most common and disruptive problems in fiber manufacturing. These breaks can occur at any point in the drawing process, from the furnace exit to the take-up reel. Understanding the different types of breaks and their causes is essential for effective troubleshooting.

Furnace-related breaks often result from defects, temperature instabilities, or contamination in the hot zone. Perform inclusions or bubbles can create stress concentrations that lead to breaks when the glass is softened. Temperature fluctuations can cause thermal shock that weakens the fiber. Contamination from furnace components or atmospheric impurities can create weak spots in the glass structure.

Drawing tension problems cause breaks throughout the fiber path. Excessive tension can exceed the fiber’s tensile strength, while sudden tension changes can create dynamic loads that cause failure. Tension variations often result from capstan speed fluctuations, dancer system problems, or take-up reel issues.

Coating-related breaks occur when the coating application process creates stress concentrations or when coating defects allow an environmental attack on the glass surface. Eccentric coating application can create bending stresses that weaken the fiber. An incomplete coating cure can result in soft spots that allow moisture penetration and stress corrosion.

Diameter Control Problems

Diameter variations can make fiber unusable for precision applications. These variations can occur over short distances (microvariations) or long distances (macrovariations), each requiring different troubleshooting approaches.

Preform-related diameter variations often result from inconsistent glass composition or geometric irregularities in the preform. Refractive index variations can affect the drawing behavior and cause diameter changes. Perform eccentricity or diameter variations will propagate directly into the drawn fiber.

Furnace temperature instabilities represent a significant cause of diameter variations. Temperature changes affect the glass viscosity, which directly impacts the drawing behavior. Furnace power fluctuations, cooling system problems, or atmospheric variations can all cause temperature instabilities.

Drawing speed control problems can create diameter variations when the feedback control system cannot respond quickly enough to process changes. Control system tuning, sensor calibration, and mechanical system maintenance all affect the diameter control performance.

Environmental factors like air currents, vibration, or temperature changes in the drawing tower can cause diameter variations. These factors often create periodic variations that can be identified through frequency analysis of the diameter measurements.

| Problem Type | Common Causes | Diagnostic Methods | Solutions |

|---|---|---|---|

| Fiber breaks8 | Preform defects, tension issues | Visual inspection, tension monitoring | Preform quality control, tension adjustment |

| Diameter variation | Temperature instability, speed control | Real-time diameter monitoring | Temperature control, PID tuning |

| Coating defects | Die misalignment, cure problems | Coating thickness measurement | Die adjustment, UV lamp maintenance |

| Attenuation increase | Contamination, stress | Optical testing, microscopy | Cleanliness protocols, stress relief |

Coating Application Problems

Coating defects can affect both the optical and mechanical properties of the finished fiber. These problems often develop gradually, making early detection essential for preventing large quantities of defective products.

Coating thickness variations can result from die wear, pressure fluctuations, or material property changes. Die wear typically creates gradual thickness changes over time, while pressure fluctuations cause more rapid variations. Material viscosity changes due to temperature or aging can also affect coating thickness.

Coating concentricity problems occur when the fiber is not properly centered in the coating die or when the die itself is not aligned correctly. These problems create eccentric coatings that can cause polarization mode dispersion in single-mode fibers and handling difficulties in all fiber types.

Coating cure problems can result from UV lamp aging, nitrogen atmosphere contamination, or coating material degradation. An incomplete cure creates tacky surfaces and poor mechanical properties. Overture can make the coating brittle and prone to cracking.

Coating adhesion problems can develop when the glass surface is contaminated or when the coating material has degraded. Poor adhesion can lead to coating delamination during handling or environmental exposure.

Systematic Troubleshooting Approach

Effective troubleshooting requires a systematic approach that considers all possible causes and uses data to guide the investigation. I always start by gathering as much information as possible about when the problem started, what conditions were present, and what changes might have occurred.

Data analysis plays a crucial role in identifying problem patterns. Trending charts can reveal gradual changes that might not be obvious from individual measurements. Correlation analysis can identify relationships between different parameters that suggest root causes.

Process elimination helps narrow down the possible causes by systematically ruling out different systems. For example, if diameter variations occur only during specific preform batches, the problem likely relates to preform quality rather than drawing equipment.

Root cause analysis techniques like fishbone diagrams or five-why analysis help ensure that solutions address the underlying causes rather than just the symptoms. This approach prevents problems from recurring and builds an understanding of the process interactions.

Preventive Maintenance Strategies

Preventive maintenance programs help avoid many common manufacturing problems by addressing potential issues before they cause production disruptions. These programs should be based on equipment manufacturer recommendations, historical failure data, and process requirements.

Scheduled maintenance activities include regular calibration of measurement systems, replacement of worn components, and cleaning of critical areas. The maintenance schedule should consider both time-based and usage-based intervals to optimize equipment reliability.

Condition monitoring techniques can identify developing problems before they cause failures. Vibration analysis can detect bearing wear or alignment problems. Thermal imaging can locate electrical problems or cooling system issues. Oil analysis can reveal internal wear in hydraulic or lubrication systems.

Spare parts inventory management ensures that critical components are available when needed for maintenance or emergency repairs. The inventory should include both routine maintenance items and necessary spare parts that could cause extended downtime if not available.

Training programs ensure that operators and maintenance personnel understand proper procedures and can recognize early signs of developing problems. Regular training updates help maintain skills and introduce new techniques or technologies.

Documentation systems track maintenance activities, problem history, and equipment performance trends. This information helps optimize maintenance schedules, identify recurring problems, and support continuous improvement efforts.

Conclusion

Successful fiber core manufacturing requires precise control of materials, equipment, and processes throughout the entire production chain.

-

Explore this resource to understand the latest techniques and innovations in fiber core manufacturing, ensuring high quality and efficiency. ↩ ↩ ↩

-

Discover the stringent purity requirements for optical fiber materials to ensure high performance and reliability in fiber optics. ↩

-

Understanding the MCVD process is crucial for anyone interested in high-quality optical fiber production, as it outlines the foundational techniques used in the industry. ↩

-

Exploring the OVD process reveals its benefits for producing large preforms, which can enhance your knowledge of advanced fiber manufacturing techniques. ↩ ↩

-

Learning about fiber drawing towers is essential for understanding the equipment that ensures high-quality fiber production, impacting overall manufacturing success. ↩

-

Explore how Statistical Process Control can enhance manufacturing efficiency and product quality through data-driven insights. ↩

-

Learn how Automated Quality Systems can streamline production, reduce errors, and ensure consistent quality in manufacturing. ↩

-

Understanding the causes of fiber breaks can help in implementing effective solutions and improving production reliability. ↩ ↩ ↩