Wrong equipment choices cost manufacturers $300,000. Different cable types need different machines. I’ll show you the exact equipment selection method.

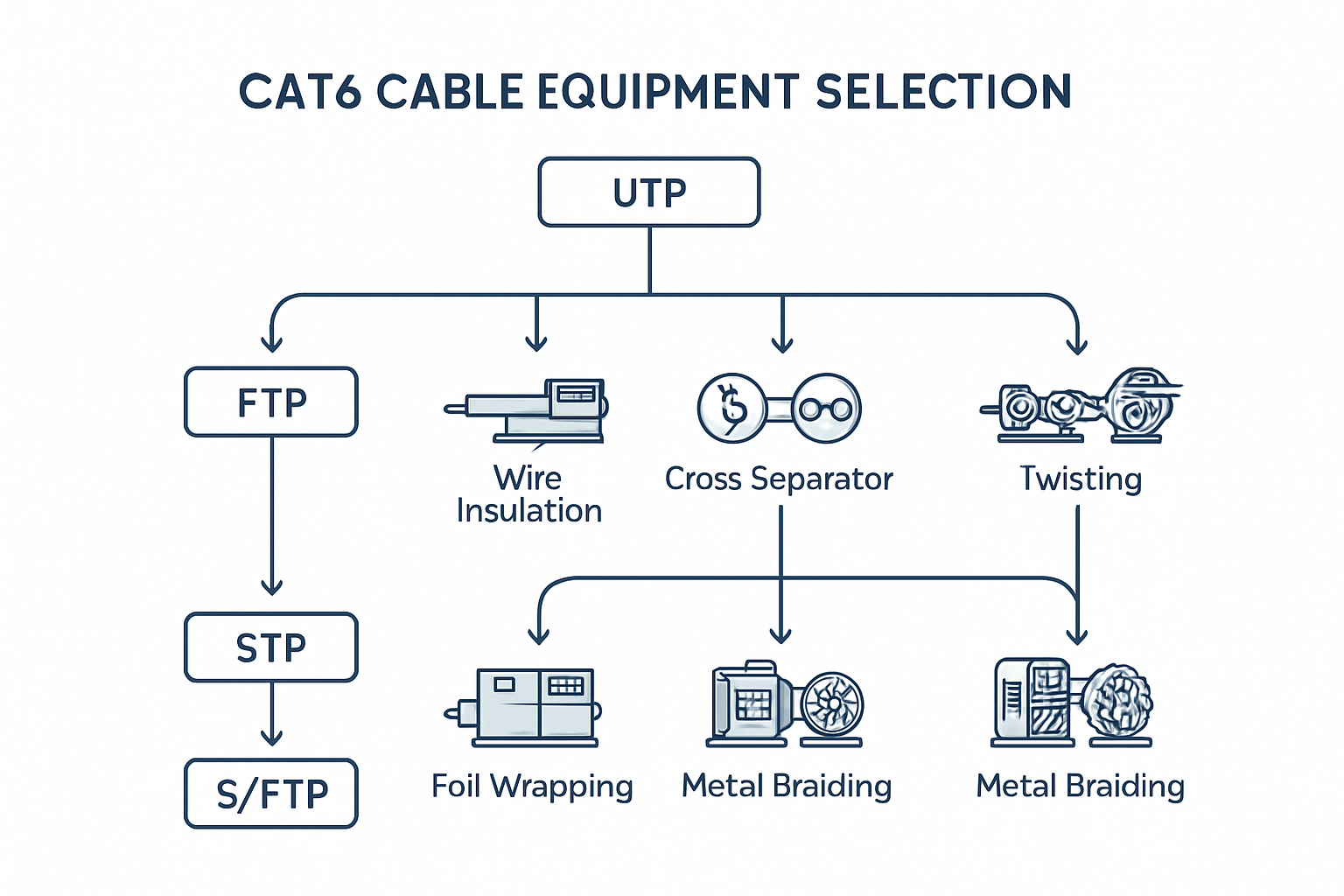

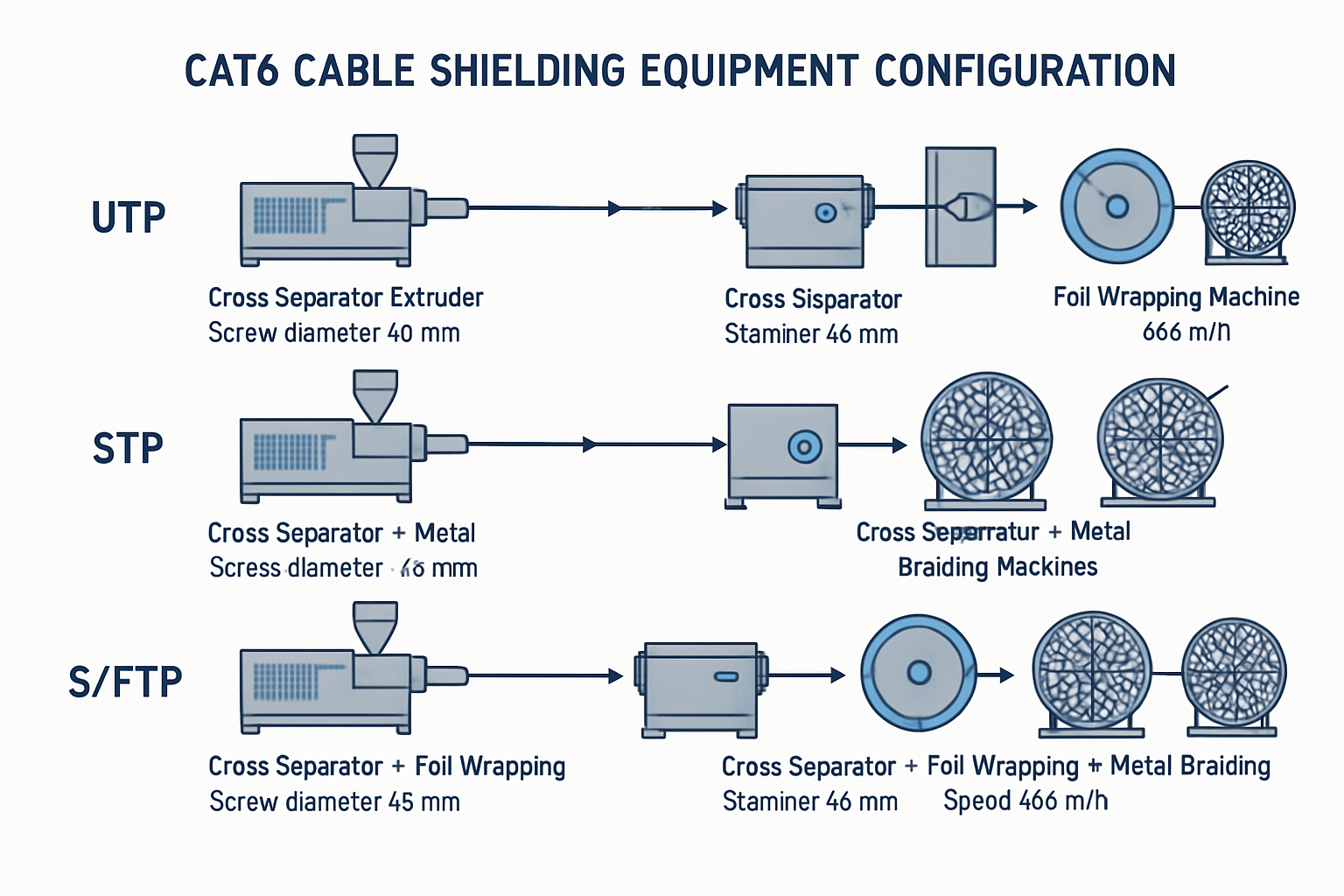

Cat6 equipment varies by type: UTP needs 4 machines, FTP adds foil equipment, STP requires braiding machines. Calculate quantities using: Required Machines = Production Demand ÷ Machine Capacity.

When I started helping manufacturers in 2019, I made a critical error. I recommended the same equipment configuration to everyone. A customer wanted to produce SFTP cables but I only quoted UTP equipment. They lost a major contract because their cables lacked proper shielding. That mistake taught me the importance of understanding different Cat6 specifications before recommending equipment.

What Are the Different Types of Cat6 Cables and Their Equipment Requirements?

Cable specifications confuse manufacturers. Wrong choices mean failed certifications. I’ll explain each type clearly.

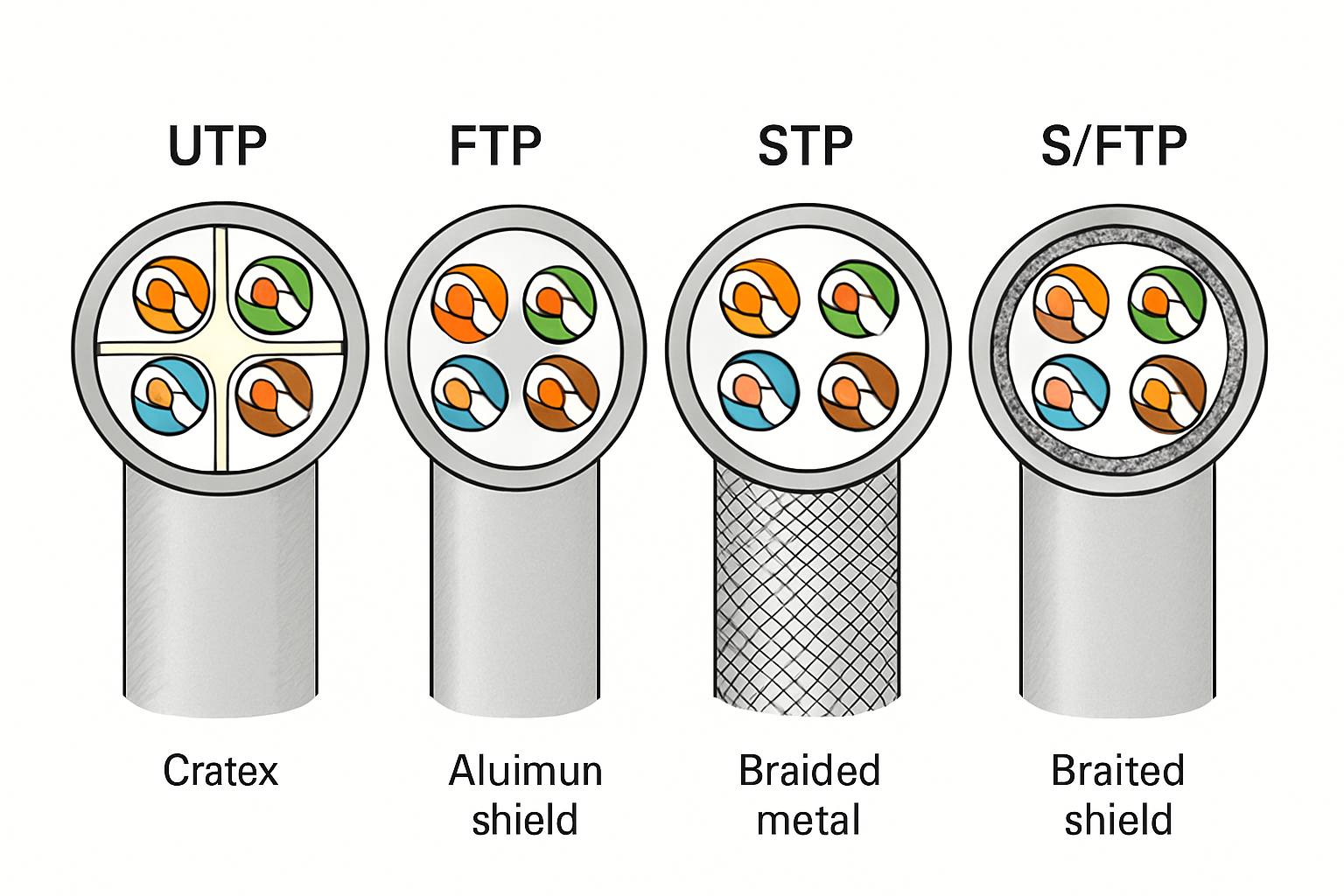

Four Cat6 types exist: UTP (basic), FTP (foil shielded), STP (braided), SFTP (double shielded). Each requires specific additional equipment beyond basic production line.

UTP (Unshielded Twisted Pair) – The Foundation Configuration

UTP represents the most basic Cat6 configuration, but don’t mistake basic for simple. These cables still require precise manufacturing to meet Cat6 performance standards. I always recommend starting with UTP production because it teaches fundamental processes without additional complexity.

The UTP structure includes four twisted pairs, a cross-shaped separator, and an outer jacket. This seems straightforward, but each component requires specific equipment and precise control. The cross separator is crucial for Cat6 performance, physically separating pairs to reduce crosstalk.

For UTP production, you need the core equipment set: copper wire insulation line, cross frame extruding machine, twisting machines, stranding machine, and sheathing line. This configuration handles most commercial applications and represents the lowest investment threshold for entering Cat6 manufacturing.

| UTP Component | Equipment Required | Function | Critical Parameters |

|---|---|---|---|

| Insulated Conductors | Φ50+35 PLC Insulation Line | Apply HDPE insulation | Thickness: 0.2mm ±0.01mm |

| Cross Separator | 50# Cross Frame Extruder | Create physical separation | Position accuracy: ±0.1mm |

| Twisted Pairs | Φ500mm Twisting Machines | Form twisted pairs | Twist rate: 12-16/meter |

| Cable Core | Φ800mm Stranding Machine | Combine pairs with separator | Tension control: 2-3 lbs |

FTP (Foiled Twisted Pair) – Adding EMI Protection

FTP cables add aluminum foil shielding around the four-pair core. This provides electromagnetic interference protection for environments with moderate EMI concerns. I often recommend FTP for office buildings near radio transmitters or industrial facilities.

The foil shielding requires additional equipment beyond the UTP configuration. You need foil tape application machinery that wraps aluminum tape around the cable core before applying the outer jacket. This equipment must maintain precise tension to prevent wrinkles or gaps in the foil coverage.

Foil application adds complexity to the production process. The aluminum tape must overlap correctly to provide continuous shielding. Any gaps or tears in the foil compromise the cable’s EMI protection. I learned this when a customer’s FTP cables failed EMI testing due to poor foil application.

The foil also requires a drain wire for grounding purposes. This bare copper wire runs alongside the foil and connects to ground at both cable ends. Your equipment must position this drain wire correctly during the foil application process.

STP (Shielded Twisted Pair) – Individual Pair Protection

STP cables feature individual foil shields around each twisted pair, plus an overall braided shield. This configuration provides superior EMI protection compared to FTP cables. I recommend STP for industrial environments with high electromagnetic interference.

Individual pair shielding requires specialized equipment that applies foil to each pair separately. This happens after pair twisting but before stranding. The equipment must handle four separate foil application processes simultaneously while maintaining proper tension and overlap.

The overall braided shield uses the metal braiding machine from our equipment list. This machine weaves copper or tinned copper wires around the cable core. The braiding process requires precise control of wire tension and weave pattern to ensure consistent coverage.

Metal braiding significantly impacts production speed. While other processes run at 50-90 meters per minute, braiding typically operates at 5 meters per minute. This creates a production bottleneck that requires multiple braiding machines for higher capacity lines.

How Do You Calculate Equipment Quantities Based on Production Requirements?

Wrong calculations create bottlenecks. Manufacturers buy insufficient equipment. I’ll show you the exact calculation formula.

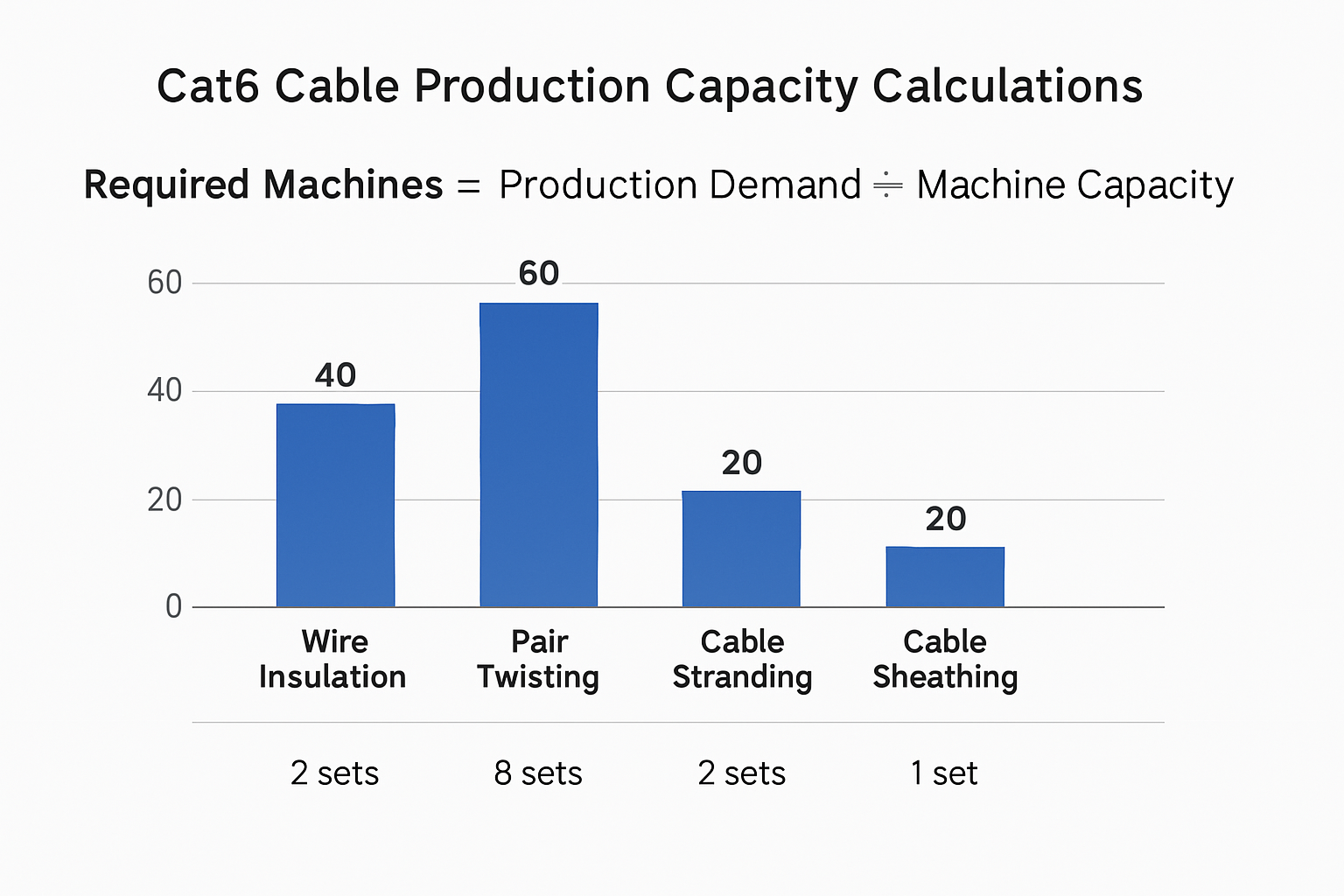

Formula: Required Machines = Production Demand ÷ Machine Capacity. For 10,000 boxes monthly: need 8 twisting machines, 2 stranding machines.

Understanding Production Capacity Calculations

The key to proper equipment sizing lies in understanding each machine’s actual production capacity and how they interact in the production line. I use a systematic approach that considers machine speeds, working hours, and production efficiency factors.

Let me walk you through a real example. A customer wanted to produce 10,000 boxes of Cat6 cable monthly. Each box contains 305 meters, so total monthly production equals 3,050 kilometers. This seems straightforward until you consider that different processes require different amounts of material.

For the copper wire insulation process, you need 8 insulated conductors for each meter of finished cable. So 3,050 km of finished cable requires 24,400 km of insulated wire. The Φ50+35 PLC insulation line produces 500 meters per minute, which equals 18,720 km per month assuming 26 working days and 24-hour operation.

The calculation shows you need 24,400 ÷ 18,720 = 1.3 machines. Since you cannot buy 1.3 machines, you need 2 insulation lines to meet production requirements. This provides some capacity buffer for maintenance and efficiency losses.

| Process Step | Material Requirement | Machine Capacity | Machines Needed | Actual Configuration |

|---|---|---|---|---|

| Wire Insulation | 24,400 km (8 cores) | 18,720 km/month | 1.3 | 2 sets |

| Pair Twisting | 12,200 km (2 cores) | 1,500 km/month | 8.1 | 8 sets |

| Cable Stranding | 3,050 km (4 pairs) | 1,872 km/month | 1.6 | 2 sets |

| Cable Sheathing | 3,050 km (final) | 3,369 km/month | 0.9 | 1 set |

Bottleneck Analysis and Line Balancing

The twisting process creates the biggest bottleneck in Cat6 production. Each finished cable requires four twisted pairs, but each twisting machine only produces one pair at a time. This means you need multiple twisting machines running simultaneously to feed the stranding process.

I learned about bottlenecks the hard way. A customer ordered equipment based on final cable requirements without considering intermediate processes. They bought one twisting machine for a 1,000 km monthly line. When production started, the single twisting machine could only supply 1,500 km monthly, but they needed 4,000 km of twisted pairs (1,000 km × 4 pairs).

The solution required purchasing three additional twisting machines, delaying production startup by two months. The customer lost a major contract due to delivery delays. This experience taught me to always calculate equipment requirements for each process step separately.

Production line balancing requires matching machine capacities at each step. The slowest process determines overall line speed. In most Cat6 lines, metal braiding (for STP/SFTP cables) creates the biggest constraint at 5 meters per minute compared to 50-90 meters per minute for other processes.

Efficiency Factors and Capacity Planning

Theoretical machine capacity differs significantly from actual production capacity. I use efficiency factors to account for setup time, maintenance, material changes, and operator breaks. A typical efficiency factor ranges from 75-85% depending on operation maturity and automation level.

New operations typically achieve 75% efficiency during the first year. Experienced operations with well-trained operators and preventive maintenance programs can reach 85% efficiency. I always recommend planning for 80% efficiency when calculating equipment requirements.

Material waste also affects capacity calculations. Wire drawing and insulation processes typically have 2-3% waste. Twisting and stranding add another 1-2% waste. Sheathing processes contribute 1-2% additional waste. Total waste can reach 5-7% of raw material input.

Quality control requirements further impact effective capacity. Each production lot requires testing time and potential rework. I recommend adding 5-10% capacity buffer for quality control activities and potential rework requirements.

When Should You Include Wire Drawing Equipment in Your Production Line?

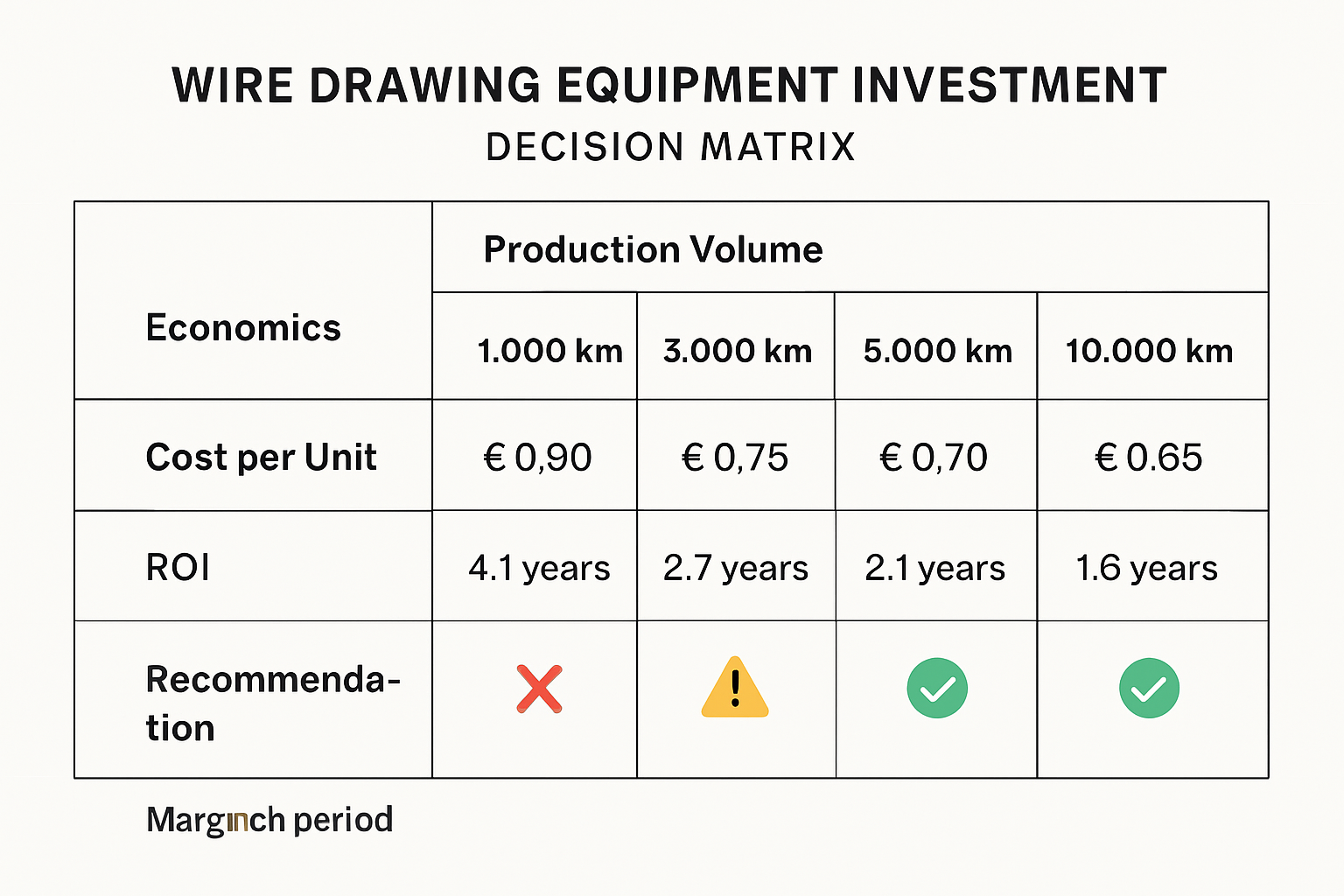

Wire drawing affects costs and quality. Many manufacturers struggle with this decision. I’ll share my decision framework.

Include wire drawing for custom sizes, quality control, high volumes (>5,000 km monthly). Skip for standard specs, low volumes, limited budgets.

Cost-Benefit Analysis of Wire Drawing Integration

Wire drawing equipment represents a significant additional investment, typically $150,000-$300,000 for a complete line including annealing and quality control systems. This investment only makes sense when the benefits justify the additional complexity and cost.

I helped a customer analyze wire drawing economics for their 8,000 km monthly Cat6 production. Purchasing standard 23 AWG wire cost $6.50 per kilogram. Drawing from 8mm copper rod reduced material cost to $5.80 per kilogram, saving $0.70 per kilogram or $5,600 monthly on copper alone.

The wire drawing equipment cost $220,000 including installation and training. At $5,600 monthly savings, the payback period was 39 months. However, the customer also gained quality control benefits and supply chain independence that justified the investment.

Wire drawing becomes more attractive at higher production volumes. The fixed costs of equipment and operation spread across more production, reducing per-unit costs. I generally recommend wire drawing for operations exceeding 5,000 km monthly production.

| Production Volume | Wire Drawing Economics | Recommendation |

|---|---|---|

| <2,000 km/month | High per-unit cost | Purchase wire |

| 2,000-5,000 km/month | Marginal economics | Depends on quality needs |

| 5,000-10,000 km/month | Good economics | Consider wire drawing |

| >10,000 km/month | Excellent economics | Strongly recommend |

Quality Control Advantages

Wire drawing provides complete control over conductor quality, which directly impacts cable performance. When you purchase wire from suppliers, you depend on their quality control systems. Wire drawing lets you control diameter tolerance, surface finish, and mechanical properties.

I worked with a customer who experienced quality problems with purchased wire. The supplier’s diameter tolerance was ±0.02mm, but Cat6 performance required ±0.01mm tolerance. The loose tolerance caused impedance variations that failed certification testing.

Installing wire drawing equipment solved the quality problem. The customer achieved ±0.005mm diameter tolerance, well within Cat6 requirements. This improved cable performance and reduced testing failures from 8% to less than 1%.

Wire drawing also enables custom alloy specifications. Some applications require specific copper alloys for enhanced performance or environmental resistance. Wire suppliers typically stock standard alloys, but custom alloys require minimum order quantities that may exceed your needs.

Supply Chain Considerations

Wire drawing reduces dependence on wire suppliers and provides supply chain flexibility. Copper rod is more widely available than precision wire, giving you more supplier options and potentially better pricing.

During the 2021 copper shortage, many wire suppliers experienced delivery delays and quality problems. Customers with wire drawing capability continued production while others faced shutdowns. The supply chain independence proved valuable beyond normal cost considerations.

Wire drawing also enables just-in-time production strategies. You can draw wire as needed rather than maintaining large wire inventories. This reduces working capital requirements and eliminates wire aging concerns.

However, wire drawing adds operational complexity. You need additional skilled operators, maintenance capabilities, and quality control procedures. The learning curve can extend startup time and increase initial operating costs.

How Do You Configure Equipment for Different Shielding Requirements?

Shielding equipment confuses manufacturers. Wrong choices cause production problems. I’ll explain exact equipment needs for each type.

UTP needs cross separator only. FTP adds foil machinery. STP requires 5 braiding machines for 3,050 km monthly. SFTP combines both.

Cross Separator Requirements for All Cable Types

Every Cat6 cable type requires a cross-shaped separator to maintain pair separation and meet performance specifications. This plastic separator runs the length of the cable and physically separates the four twisted pairs to reduce crosstalk.

The 50# cross frame extruding machine produces this separator using low-density polyethylene material. The separator must maintain precise dimensions throughout the cable length. Any variation in separator size or position affects cable geometry and electrical performance.

I learned about separator importance when a customer’s cables failed crosstalk testing. Investigation revealed that their separator extrusion machine had worn dies that produced oversized separators. The larger separator pushed pairs closer together, increasing crosstalk beyond Cat6 limits.

Separator extrusion requires careful temperature control to maintain material properties. LDPE extrusion temperature typically ranges from 160-180°C. Higher temperatures degrade the material and affect separator flexibility. Lower temperatures cause poor material flow and dimensional instability.

| Separator Parameter | Specification | Impact on Performance | Control Method |

|---|---|---|---|

| Cross Arm Thickness | 0.8mm ±0.1mm | Pair separation distance | Die precision |

| Material Density | 0.92-0.94 g/cm³ | Dielectric properties | Material selection |

| Extrusion Temperature | 160-180°C | Material properties | Temperature control |

| Line Speed | 120 m/min | Production capacity | Speed matching |

Foil Shielding Equipment for FTP and SFTP Cables

Foil shielding provides electromagnetic interference protection by creating a conductive barrier around the cable core. The aluminum foil must completely surround the four-pair core with proper overlap to ensure continuous shielding effectiveness.

Foil application equipment applies adhesive-backed aluminum tape around the cable core. The tape width must exceed the cable core diameter to provide adequate overlap. Typical overlap ranges from 15-25% of tape width to ensure complete coverage even with minor positioning variations.

The foil application process requires precise tension control to prevent tape stretching or tearing. Excessive tension causes tape breaks that interrupt production. Insufficient tension creates loose wrapping that compromises shielding effectiveness and may cause tape unwinding during subsequent processes.

I helped a customer solve foil application problems that caused 15% production waste. Their tension control system was inadequate for the thin aluminum tape they were using. We upgraded to a servo-controlled tension system that reduced waste to less than 2%.

Foil shielding also requires a drain wire for electrical grounding. This bare copper wire runs alongside the foil and provides a low-resistance path to ground. The drain wire must maintain contact with the foil throughout the cable length.

Metal Braiding for STP and SFTP Configurations

Metal braiding provides superior EMI protection compared to foil shielding but requires specialized equipment and significantly impacts production speed. The braiding process weaves copper or tinned copper wires around the cable core in a specific pattern.

The 800# metal braiding machine operates at only 5 meters per minute compared to 50-90 meters per minute for other processes. This slow speed creates a major production bottleneck that requires multiple braiding machines for higher capacity lines.

For 3,050 km monthly production, you need 5 metal braiding machines based on the speed differential. Each machine produces 1,872 km monthly (5 m/min × 60 min/hr × 24 hr/day × 26 days), so 3,050 ÷ 1,872 = 1.6 machines. However, you need 5 machines because braiding is the bottleneck process.

Braiding wire selection affects both performance and cost. Bare copper provides the best conductivity but may tarnish over time. Tinned copper resists tarnish but costs more and has slightly higher resistance. Silver-plated copper offers the best performance but significantly increases material cost.

The braiding pattern affects shielding effectiveness and mechanical properties. Tighter braids provide better shielding but reduce cable flexibility. Looser braids maintain flexibility but may have shielding gaps. I recommend 85-90% optical coverage for most Cat6 applications.

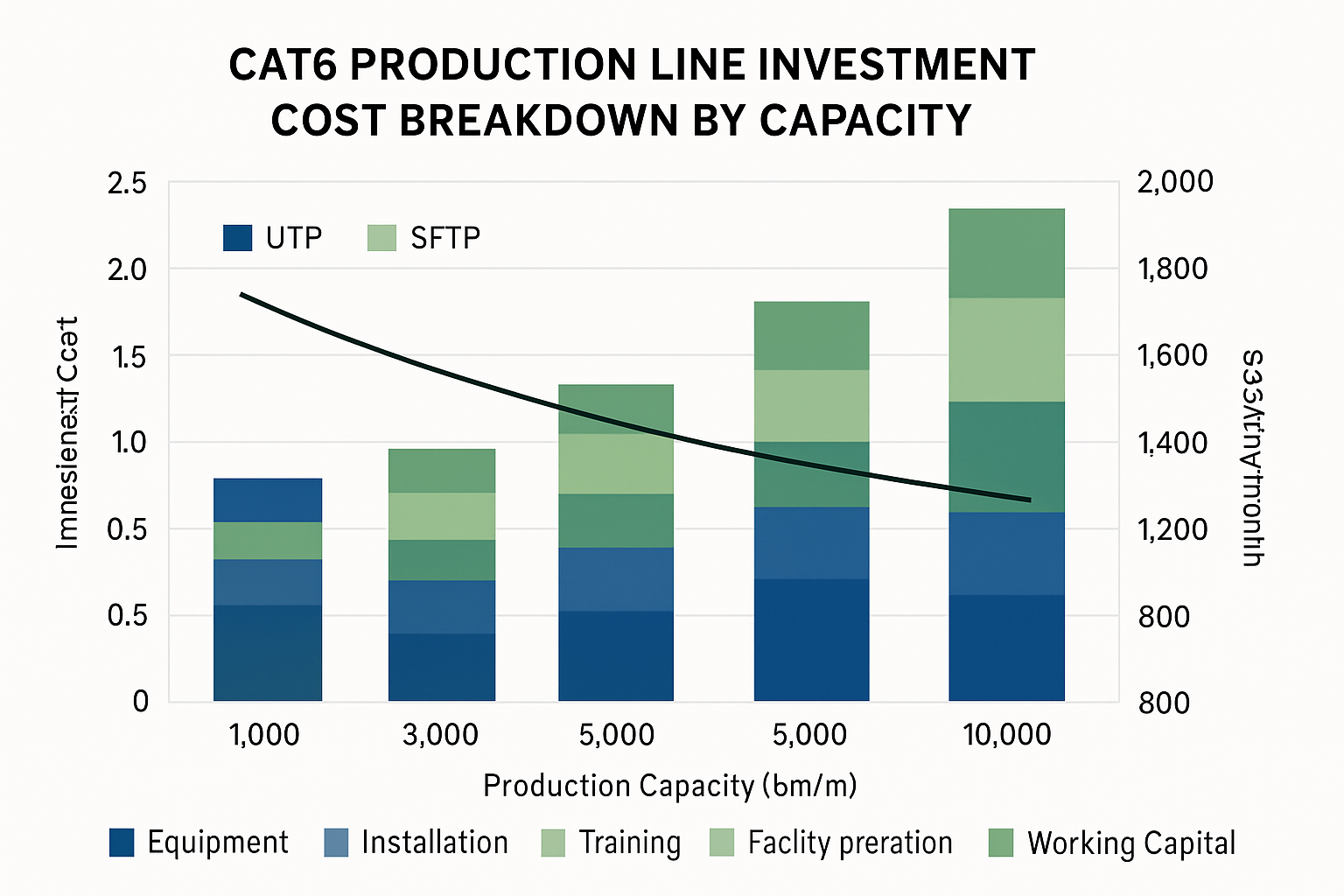

What Investment Levels Should You Expect for Different Production Capacities?

Investment planning determines project success. Manufacturers underestimate costs by 40%. I’ll share real investment numbers from actual projects.

UTP production (3,000 km monthly): $280,000-$350,000. SFTP same capacity: $450,000-$580,000. High capacity (10,000 km): $650,000-$950,000.

Equipment Cost Breakdown by Production Capacity

Equipment costs scale with production capacity, but not linearly. Higher capacity lines benefit from economies of scale in some components while requiring multiple units of bottleneck equipment. Understanding this relationship helps optimize your investment.

For a 3,000 km monthly UTP line, the basic equipment set costs approximately $280,000. This includes one Φ50+35 insulation line ($85,000), four Φ500mm twisting machines ($180,000), one Φ800mm stranding machine ($45,000), and one Φ80mm sheathing line ($65,000). Quality control equipment adds another $35,000.

Scaling to 10,000 km monthly requires additional equipment due to bottleneck processes. You need two insulation lines, eight twisting machines, two stranding machines, and one sheathing line. The total equipment cost reaches approximately $650,000, representing a 2.3x increase for 3.3x capacity.

The non-linear scaling occurs because some equipment (like sheathing lines) has excess capacity at lower production levels. Other equipment (like twisting machines) requires multiple units even for basic production. Understanding these relationships helps optimize equipment selection.

| Production Capacity | UTP Equipment Cost | SFTP Equipment Cost | Cost per km/month |

|---|---|---|---|

| 1,000 km/month | $180,000-$220,000 | $280,000-$350,000 | $180-$350 |

| 3,000 km/month | $280,000-$350,000 | $450,000-$580,000 | $93-$193 |

| 5,000 km/month | $420,000-$520,000 | $680,000-$850,000 | $84-$170 |

| 10,000 km/month | $650,000-$800,000 | $950,000-$1,200,000 | $65-$120 |

Additional Investment Requirements

Equipment costs represent only 60-70% of total project investment. Additional costs include facility preparation, installation, training, working capital, and startup expenses. These costs often surprise new manufacturers who focus only on equipment pricing.

Facility preparation typically costs $50,000-$150,000 depending on existing infrastructure. You need adequate electrical power (typically 500-1000 kW), compressed air systems, cooling systems, and proper ventilation. Floor loading capacity must support heavy equipment, and ceiling height must accommodate material handling systems.

Installation and commissioning add 15-20% to equipment costs. This includes equipment transportation, installation, calibration, and initial testing. Experienced suppliers provide turnkey installation, but you should budget for potential delays and additional requirements.

Operator training is crucial for successful startup but often underestimated. Plan for 2-4 weeks of intensive training for key operators and maintenance personnel. Training costs include instructor fees, travel expenses, and lost production during the learning period.

Working capital requirements depend on your payment terms with suppliers and customers. Raw materials typically require 30-60 days inventory, representing $100,000-$300,000 for a medium-scale operation. Customer payment terms may require additional working capital for accounts receivable.

Return on Investment Analysis

ROI calculations must consider both revenue potential and operating costs to provide realistic projections. I use a comprehensive model that includes material costs, labor, utilities, maintenance, and overhead to calculate true profitability.

Cat6 cable pricing varies significantly by market segment and quality level. Standard UTP cables sell for $0.15-$0.25 per foot wholesale. Plenum-rated cables command $0.30-$0.50 per foot. Specialty applications like outdoor or industrial cables can reach $0.75-$1.25 per foot.

Material costs typically represent 65-75% of production costs. Copper prices fluctuate significantly, affecting profitability. I recommend establishing copper hedging strategies or pass-through pricing mechanisms to manage commodity risk.

A well-managed Cat6 operation can achieve 25-35% gross margins on standard products and 40-50% on specialty cables. However, achieving these margins requires efficient operations, quality control, and effective marketing.

Based on my experience with 50+ installations, typical payback periods range from 18-36 months depending on market conditions, product mix, and operational efficiency. Operations focusing on high-value specialty cables achieve faster payback than commodity producers.

Conclusion

Successful Cat6 production requires matching equipment to cable types and calculating quantities based on actual capacity needs and bottleneck analysis.

About Peter He

I’m Peter He, founder of HONGKAI Cable Machinery Solutions with 8 years of experience in cable production equipment. Since 2017, I’ve helped over 100 manufacturers establish successful Cat6 production operations worldwide.

At HONGKAI, we specialize in complete cable machinery solutions from equipment selection through production optimization. Our technical expertise covers all Cat6 cable types including UTP, FTP, STP, and SFTP configurations.

I started my journey in international trade in 2017, established HONGKAI’s online presence in 2019, and built our reputation through the challenging pandemic years. My mission is helping manufacturers achieve success through proper equipment selection and technical support.

Whether you’re planning your first Cat6 production line or expanding existing operations, I provide personalized guidance based on real-world experience. Every project receives my direct attention because your success drives our growth.

For detailed equipment specifications, capacity calculations, and investment analysis, visit www.hkcablemachine.com or contact me directly. I personally respond to every inquiry with customized recommendations for your specific requirements.